Operational Management

Optimize Your Operations with Expert Strategic CFO Services

Operations managers wear many hats. They manage information, human resources, and the equipment and technology needed for production.

Operations managers apply these responsibilities in an efficient manner to produce goods at a lower cost and or higher quality than competitors while meeting deadlines.

Operations managers must have a firm understanding of your business procedures. They should maximize your company’s efficiency, increase productivity, increase profits (and reduce costs), and deliver high

quality products and services to your customers.

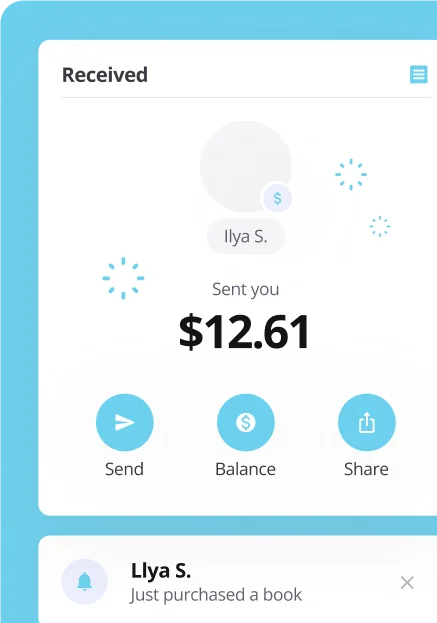

At Fully Accountable, our outsourced CFO services provide the framework you need to maximize your business growth. With data-driven operational strategies and a commitment to actionable insights, our operational management services optimize your products and services so you can take on the

competition with confidence.

Proper Operations Management can help you:

What Does an Operational Manager Do?

Chief Operations Officer

The Chief Operations Officer (COO) ensures every aspect of an organization runs smoothly and in accordance with expectations. The operational CFO reports to the CEO and, work together to identify problems before they it becomes too big or expensive for either party involved.

The high-ranking executive position known as “COO” has many responsibilities including managing day-to-day work while ensuring all operations meet

company standards.

Operations Manager

Functions of Operational

Management

Operations management is the art of ensuring your business runs smoothly. Your CFO fulfills various roles, including strategic functions, such as planning and budgeting for projects across different departments within an organization.

Functions of Operational Management Include:

Product Development

The operations manager’s responsibility for product development ensures consumers get what they were promised as well matching trends of today’s market place with high quality goods.

Product development often starts by generating lots of ideas and narrowing down which ones are going to appeal most widely among potential buyers.

Forecasting

Supply Chain Management

Additionally, they track damaged or lost goods that were created on the supply chain so they can replace them expediently. The operations manager also monitors pricing trends within different industry sectors carefully, enabling him/her to make more effective decisions on impending

contract negotiations.

Delivery Management

Optimize Your Operations and Maximize Your Business’s Potential

At Fully Accountable, we believe businesses of all sizes should have access to strategic CFO services that improve your business from top-to-bottom. If you want improved operations and standardized procedures, our team of financial professionals is here to deliver.